Hi all smarter than me  Looking for what your thoughts and take is on sealing joints of a concrete driveway within a park. My past experience has been this that I learned from an asphalt company. Clean it , and then there is a machine that maybe is on a trailer and its like a hot sealant and then get that into the cracks.

Looking for what your thoughts and take is on sealing joints of a concrete driveway within a park. My past experience has been this that I learned from an asphalt company. Clean it , and then there is a machine that maybe is on a trailer and its like a hot sealant and then get that into the cracks.

Then talking with a concrete vendor, he said to clean it, pack in 1/2 inch of sand then use the cold rubber caulking product.

Looking at a city street, it appears this hot asphalt sealant method would have been used.

Does anyone have any recommendations on this? And its it typically an asphalt vendor that does it, handy man, what the specific material is , if you recommend cold, what the product name is , etc. ?

I was told this is a good preservation tool of a property to minimize water intrusion thus leading to base failure.

Or is this all hocus pocus and not worth the extra work and expense for longevity. I would think if I have seen cities doing it , makes sense.

Lastly, if you know what price linear foot is in line please share that. If there is a recommended minimum crack size to cover or only joints or craxk size needs to be X, also appreciated. Thanks Picture of the one with it is a city street, the picture with the re pour of section is a sample fo the subject property.

1 Like

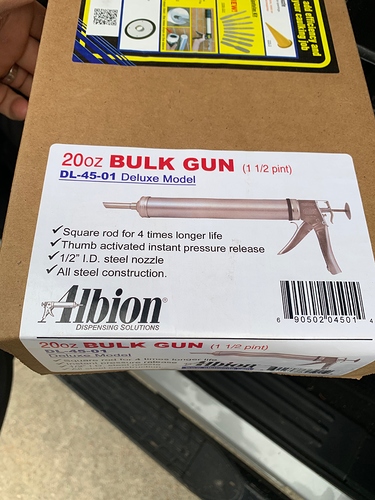

Ok, one of the guys that attends the real estate group i attend actually inspects highway new construction here in Texas. I mentioned this to him and off the top of his head he mentioned a product called 890 Self Leveling and just like for certain approved items for MH installation, is the same for states list of approved items for road work .

So all of this is probably way above for whats required in a mobile home park. He also went on to talk about the process with a backer rod beneath ,and the product they use out there is an 890 self leveling. quick google check looks like this product pops up on other state department of transportation websites .

And here in TX also found this https://ftp.dot.state.tx.us/pub/txdot-info/cmd/mpl/jtsealrs.pdf which has an array of products.

If you are really interested, here is a 20 plus report on everything you would want to know lol

It looks a little pricey at 30 plus for a tube of caulking or almost 2k for a 50 gallon drum.

I think ill see if i can find one of these vendors who maybe does it and see if i can get them to do the whole application with the cleaning , backer rod, spacing etc. I dont want to spend a fortune, im just thinking that maybe the expense is worthwhile on preservation against water intrusion and failure of the base and save from the big remove and replace expenses down the road.

1 Like

Ahh, looks like something like this for a backer rod. Amazon.com

This seems pretty straight forward I may not look for an outside company to do this. I just have to read up a little on the cleaning process.

1 Like

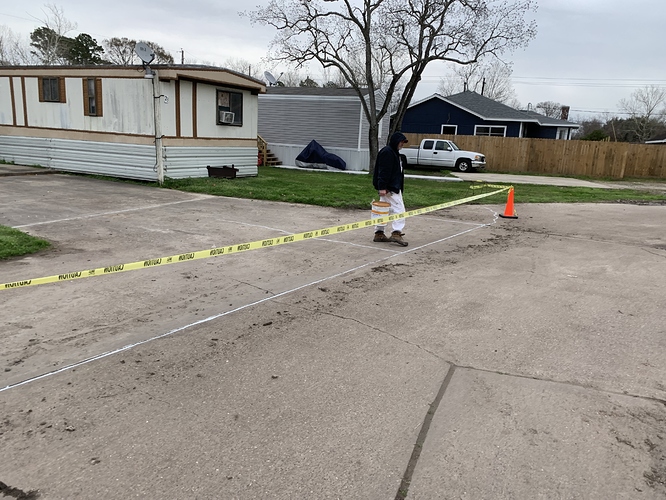

Ok just an update. While i wasn’t planning on doing this i have family visiting from up north and they dont mess around when it comes to working lol. We made a couple calls and next thing we know we were at it. We ended up using a product called Master Seal SL 1 which is what they said to use, about 1/2 the price of the 890 self leveling. we bought from http://cmcconstructionservices.com They were helpful. I told her about the 890 and she said TDOT usually uses that because of flexibility ( silicone) verus this product which was elastomeric ( not sure if thats the word) but like the mobile home roof sealant stuff.

We did a trial to see how it goes. Cleaning the joints was a lot of work, we bought a specific type of hammer to scrape them out, not pictured and then hit the sides with an angle grinder with wire wheel . Getting old wood forms out can be also challenging if they aren’t rotted out. There were some instructions ( not pictured) but seems like for most applications primer is not required. Then once you do that, blow them out, size the backer rod then apply the stuff. One thing we did an areas where we couldn’t have the drying time without blocking access, we sprinkled sand on them just to avoid the possibility of a mess. Not sure if that will effect end result and was about an hour to dry. Also the backer rod comes in different sizes, we got the little roller tool ( which i recommend doing for placement) . getting a mix of sizes depending on how your joints are might be a good idea. check the product instructions for proper application ( they weren’t picture on the bucket or caulk tube ) but you can probably get them online. it comes in 29 oz tubes but seems to be a lot less if you buy the bulk 5 gallon bucket. Just be ready its a PITA to reload. We did it but really most convenient for two people on reloading. Im also not sure what the longevity will be on the cracks without backer rod as we couldn’t find a specific answer to that. We came to the conclusion, that if we could power wash the joints it would cut out a ton of the prep work on joint cleaning , maybe 50 percent less work. But since we only had a few days of good weather, more of a trial, knocked out maybe a couple hundred feet. Probable have about 2,000 linear feet to do. So at some point in the coming months once we get a good TX heat , pressure wash to clean out, i think we will buy the tubes and get that knocked out in a couple days. The whole goal of this is asset preservation. So while it all might run 4k ( not sure with labor and material ) . my thought is you could save 10s of thousands in road repair by maintaining. We joked to do half the drive and leave the other half and revisit in 20 years what the results were. But obviously aren’t going to do that. Also, by revisiting in a few months, we will have a good gauge to see how everything looks and if we can get the longevity then proceed with the whole project.

Th=

2 Likes

Looking for what your thoughts and take is on sealing joints of a concrete driveway within a park. My past experience has been this that I learned from an asphalt company. Clean it , and then there is a machine that maybe is on a trailer and its like a hot sealant and then get that into the cracks.

Looking for what your thoughts and take is on sealing joints of a concrete driveway within a park. My past experience has been this that I learned from an asphalt company. Clean it , and then there is a machine that maybe is on a trailer and its like a hot sealant and then get that into the cracks.